This Two-head Foaming device is widely used as the ancillary equipment of coating production lines including carpets back coating lines, non-woven fabric backing lines, fabric coating lines and latex pillow production line and so on. This foaming machine can efficiently...

Introduction

This Two-head Foaming device is widely used as the ancillary equipment of coating production lines including carpets back coating lines, non-woven fabric backing lines, fabric coating lines and latex pillow produciton line and so on.

This foaming machine can efficiently improve the utilization of the coating process and the basic properties of the slurry or pulp. The foams generated are uniform, fine and stable. It has a built-in cooling system.

Overall dimension: 1550x1700x1200mm

Weight: 700kg

Output: 100-1500kg/h

Foaming rate: 1:1~1:30

Application material: water-based emulsion

Power: 3/N/PE, 380V

Construction material: stainless steel frame and stainless steel electric box

Cutting teeth: 4800teeth, rotary speed: 0~360 r/min

Mechanical sealing: double-end mechanical sealing

Machine Characteritics

Fully automatic

High flow

Uniform, fine and stable foaming

High efficiency

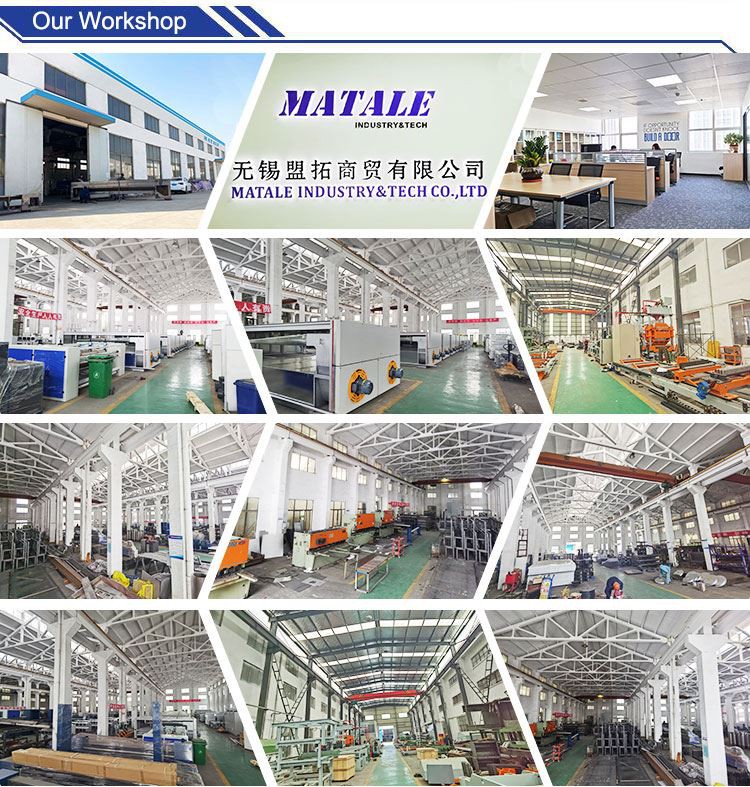

Thanks to decades years of experience on carpet industry, Matale provides customers not only advanced machines, but also design innovation and solution services.

Matale's advanced carpet back coating machines and ancillary equipment satisfy the demand from carpet tiles to patterned broadloom carpet in rug market, contract and commercial market, turf market, hospitality market, residential market and automotive market etc.

Proudly made in China, Matale will always be committed to the research and development on all unique back coating machines and ancillary equipment.

Hot Tags: two-head foaming device, Cut Pile Tufting Machine, Carpet Coating Machine, Tufting Looper, Tungsten Alloy Hook, Tufting Machine Looper, Needle Module Gauge Parts

QR Code